Table of Contents

With the arrival of Industry 4.0, Industrial Internet of Things (IIoT) Internet of Things (IoT), and Robotic Process Automation (RPA) manufacturing industries are leveraging real-time production data to make better, faster decisions and enable automation across the organization.

Equipment connected through sensors and edge devices feeds massive volumes of data to cloud-based analytics platforms, which can analyze and interpret data faster than human perception. This manufacturing data analytics can then be used to drive real-time decision-making and significant process improvements throughout the company.

Emerging technologies are generating vast amounts of big data, offering insights that are revolutionizing the manufacturing industry. However, this opportunity also presents challenges. If not effectively managed, these challenges can hinder a company’s ability to leverage the power of this data fully. According to the survey, 96% of companies are not able to leverage big data lacking the skills and technology to use their data to gain an edge over competitors.

How Does Inaccurate Data Affect The Manufacturing Industries?

Manufacturing industries face several challenges when they lack data accuracy. Some of the key issues include:

- Quality Control Problems: Incorrect data can lead to flaws in product quality as decisions are based on faulty information, resulting in defects and rework.

- Inventory Management Issues: Inaccurate data on inventory levels can lead to overstocking or stockouts, affecting production schedules and customer satisfaction.

- Forecasting and Demand Planning: Poor data accuracy hampers accurate forecasting of demand, leading to either excess inventory or missed sales opportunities.

- Operational Inefficiencies: Incorrect data can cause delays in production schedules, equipment breakdowns due to improper maintenance planning, and inefficient resource allocation.

- Compliance and Regulatory Risks: Manufacturing industries must comply with strict regulations. Inaccurate data can lead to non-compliance, fines, or legal issues.

- Supply Chain Disruptions: Inaccurate data can affect supplier relationships, logistics planning, and lead times, causing disruptions in the supply chain.

- Cost Overruns: Incorrect data can lead to cost overruns due to misallocation of resources, unplanned maintenance, or unexpected downtime.

Addressing these challenges often involves implementing robust data management practices, utilizing technologies like IoT, IIoT, and RPA for real-time data collection, and employing data analytics for better decision-making and process optimization.

Why Do Manufacturers Need Custom Data Analytics Dashboards?

Data analytics is a game-changer in manufacturing that helps achieve several key objectives. It transforms how manufacturers operate by enabling real-time monitoring and control of processes, optimizing production schedules, predicting maintenance needs, and identifying improvement opportunities.

Tailored Metrics and Key Performance Indicators (KPIs):

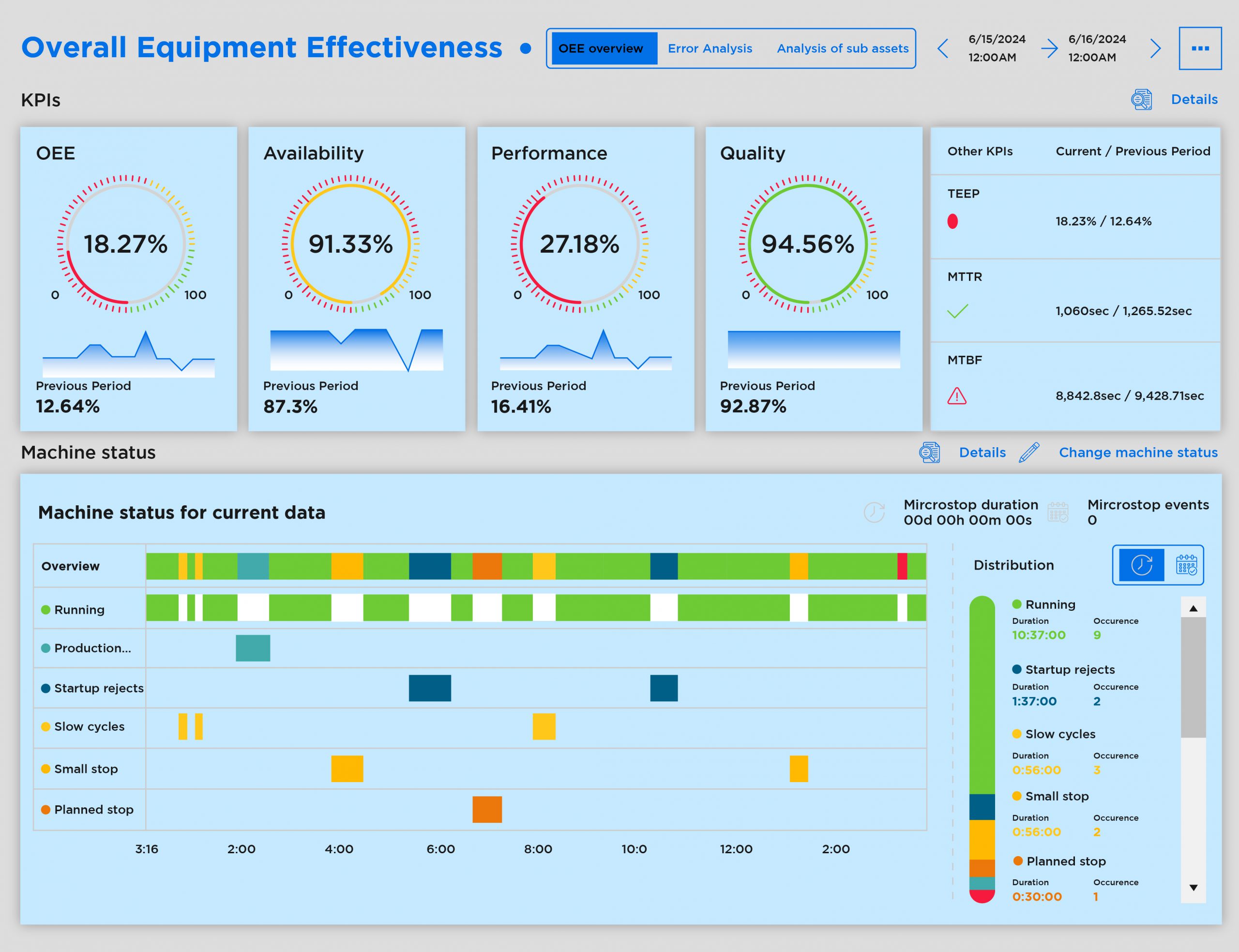

Custom dashboards in manufacturing are engineered to track industry-specific metrics such as Overall Equipment Effectiveness (OEE), First Pass Yield (FPY), and Mean Time Between Failures (MTBF). These metrics are crucial for assessing the efficiency of production lines and machinery, identifying bottlenecks, and optimizing resource utilization.

Integration with Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP):

- Custom dashboards integrate deeply with MES, ERP, and SCADA systems, allowing for seamless data flow from shop floor operations to executive decision-making. They pull real-time data on machine performance, inventory levels, and production schedules, enabling agile adjustments to production plans based on demand fluctuations and resource availability.

Advanced Analytics and Predictive Maintenance:

- Advanced analytics capabilities embedded within custom dashboards leverage techniques like machine learning algorithms for predictive maintenance. These algorithms analyze historical data on machine performance, detect patterns indicative of potential failures, and recommend proactive maintenance actions. This predictive approach minimizes unplanned downtime, enhances equipment reliability, and reduces maintenance costs.

Real-Time Monitoring and Control:

- Custom dashboards provide real-time monitoring and control functionalities crucial for maintaining optimal production conditions. They display live data streams from sensors embedded in manufacturing equipment, enabling operators to promptly detect anomalies, adjust production parameters, and ensure consistent product quality.

Customization for Industry-Specific Insights:

- These dashboards are designed to deliver role-specific insights tailored to operators, supervisors, and executives. For instance, operators may access dashboards displaying real-time metrics on machine uptime and production rates, while supervisors can review quality control metrics and throughput efficiency. Executives, on the other hand, utilize dashboards presenting aggregated KPIs across multiple production facilities for strategic decision-making.

Flexibility and Scalability:

- Custom dashboards are inherently flexible and scalable, accommodating evolving manufacturing processes, technological advancements, and organizational growth. They support seamless integration with new data sources, such as IoT-enabled devices and sensor networks, facilitating continuous improvement initiatives and fostering innovation in manufacturing practices.

Cost Efficiency and Competitive Advantage:

- By optimizing operational efficiency and minimizing downtime, custom dashboards contribute to significant cost savings in manufacturing operations. They empower manufacturers to respond swiftly to market demands, maintain high product standards, and deliver superior customer experiences. This capability enhances operational competitiveness and reinforces the organization’s position as an industry leader in terms of efficiency and innovation.

Difference Between Custom and General Data Analytics Dashboard

| Features | Custom Analytics Dashboard | General Data Analytics Dashboard |

|---|---|---|

| Metrics and KPIs | Tailored to specific manufacturing metrics and KPIs | Broad set of generic metrics and KPIs |

| Visualizations | Industry-specific visualizations (e.g., production line heatmaps) | Standard visualizations |

| Integration | Seamless integration with MES, ERP, SCADA | Basic integration with generic data sources |

| Advanced Analytics | Predictive maintenance, quality control analytics, inventory optimization | Basic analytics like trend analysis and summary statistics |

| User Customization | Customizable for different roles and departments | One-size-fits-all, limited customization |

| Scalability and Flexibility | Scalable and adaptable to growth and changes in manufacturing | Fixed structure, less adaptable |

| Real-Time Data Access | Incorporates real-time data from production lines and machinery | May lack real-time data capabilities |

| Personalization | Personalized for operators, managers, and executives | Generic, not tailored for specific user roles |

How Can Our Custom Analytics Dashboard Help Manufacturers Have 30-35% Increased Data Accuracy?

In the manufacturing industry, data analytics harnesses machine, operational, and system data to streamline production management and enhance efficiency across critical areas like maintenance, quality control, and planning. By leveraging precise, real-time data, manufacturers empower themselves to make more informed and prompt decisions.

Data capture in manufacturing analytics plays a pivotal role in optimizing equipment usage, lowering costs, driving process enhancements, minimizing human errors, and providing deep insights into machine conditions and production trends. This comprehensive approach enables accurate monitoring and strategic improvements in manufacturing operations.

Production Optimization Using AI/ML

By leveraging machine learning algorithms and real-time data integration from IoT, IIoT sensors, and ERP systems, we enable analytics dashboards to provide predictive insights leveraging data into equipment performance and maintenance needs. These predictive models utilize anomaly detection and regression analysis to forecast potential failures, enabling proactive maintenance strategies that minimize downtime and reduce maintenance costs.

What You Get?

- 25-30% increase in production capacity

- 30-35% increase in ROI

- Increase inaccurate resource allocation

25-30 % Process Improvement With AI/ML Integration

Industrial Internet of Things (IIoT) and IoT sensors, for instance, continuously transmit data that plants can utilize for real-time monitoring of machines and processes. This capability enables plants to identify inefficiencies and make informed decisions based on data, thereby optimizing production and minimizing downtime. We empower the data analytics dashboard with AI/ML algorithms and logic to churn actionable and valuable insights as well as automate the manufacturing process.

A practical example involves an automotive manufacturer facing frequent test failures on an axle assembly line. Initially perceived as a production defect, it was discovered through IIoT and AI integration that the issue lay in a specific axle carrier’s test circuit. Leveraging this technology, the manufacturer pinpointed the problematic axle carrier, established criteria for offline handling (such as failing three out of five tests), and promptly notified maintenance of a likely root cause for repair. This application illustrates how data-driven insights from IIoT and AI can drive targeted improvements in manufacturing processes.

What You Get?

- 35-30% increase in productivity

- 25-30% increase in cost savings

- Timely order delivery and customer satisfaction

25-30% Decrease In Downtimes Using AI/ML

Automated quality control has undergone significant evolution with computer vision applications. It has progressed from basic trip sensors and mechanical devices to a sophisticated array of advanced optical devices. These devices now integrate seamlessly with data collection systems, utilizing optics, temperature sensors, and cutting-edge vision technologies like thermal and infrared detection. We help you facilitate this integration to enhance precision in controlling operations and stopping mechanisms with greater accuracy.

What You Get?

- 25-30% increase in revenue and cost-savings

- 20-25% increase in machine and resource utilization

- Predictable maintenance schedules

Superior Quality Assurance Using AI/ML

Manufacturers can leverage the available data to enhance quality control by utilizing sensor information, inspection results, production data, and customer feedback. By effectively harnessing this quality-related data, manufacturers can identify leading indicators of potential issues, perform root cause analysis using historical data, and monitor quality metrics in real-time for swift problem resolution. Additionally, they can compare process parameters with quality outcomes for better corrective actions, develop predictive models to forecast and prevent defects and analyze supplier performance to predict issues and improve supplier selection, thereby avoiding supply chain disruptions.

What You Get?

- 30-35% reduction in defects and wastes

- Improved product quality

- Accuracy in compliance with standards

Tool Optimization With AI/ML Integration

Normal wear and tear on tools can disrupt manufacturing processes through failures or suboptimal performance, such as a gauge’s measured values shifting over time. Proper maintenance and continuous monitoring are essential, and big data plays a crucial role. It allows manufacturers to monitor tool parameters like temperature, pressure, and vibration to detect performance issues, predict tool life using historical and performance data for optimal replacement schedules, and analyze failure data to identify root causes and corrective actions.

What You Get?

- 25-30% enhanced equipment performance

- 20-25% increase in energy efficiency

- 25-35% increased productivity and quality

Why Is Ace Infoway Your Perfect Go-To Tech Partner?

- Specialized AI and ML Solutions: Ace Infoway offers specialized AI and machine learning (ML) solutions tailored to manufacturing industries’ needs, ensuring precision, agility, and scalability in data analytics and decision-making.

- Cost-effective AI Strategies: Ace Infoway’s AI and ML solutions are designed to optimize costs without compromising on performance. By leveraging advanced technologies and efficient data processing techniques, Ace Infoway enhances operational efficiency and maximizes ROI, offering superior cost-effectiveness compared to competitors.

- Reliability and Transparency: As a successful digital solution provider Ace Infoway has come a long way- more than 26 years. Our industry expertise, professionalism, transparency, and strive to deliver the best innovative result-oriented solutions helped us have a 93% client retention rate.

- Personalized Engagement: Our entire team pays granular attention to every detail of the project- right from conception to deployment. However, to leave no stone unturned the top brasses of the organization stay involved around all the stages of services we offer. Our clients have unhindered access to the CEO, CXO, CTO, and other top brasses of an organization during the entire project stages ensuring top-notch service and timely delivery.

Conclusion

Custom analytics dashboards provide tailored metrics, advanced analytics, and predictive maintenance capabilities, enabling manufacturers to optimize production, minimize downtime, and enhance quality control. These dashboards also offer seamless integration with MES, ERP, and SCADA systems, real-time monitoring, and industry-specific insights, ensuring flexibility and scalability.

Implementing appropriate custom data analytics dashboards leads to a 25-30% increase in production capacity, a 30-35% increase in ROI, and a significant decrease in defects, waste, and downtimes. As a manufacturer, if you are facing any challenges in leveraging your data and want to know how we can help you leverage your data to drive growth and success contact us now.