Table of Contents

For Original Equipment Manufacturers (OEMs), inventory management is critical, especially for spare parts components. Which typically have to be available at any given moment. For OEMs, having the right parts, materials, and resources at the right time and place is crucial to ensure high fill rates and limited downtime.

Poor or traditional method for inventory management goes beyond mere inconvenience, disrupted supply chains, and financial losses. According to research by Aberdeen Group, manufacturers with poor inventory practices suffer a reduction of approximately 30% in potential profit.

Integrating advanced tracking systems, Radio Frequency Identification (RFI), and automating processes is a first step towards streamlining inventory management. Still, inventory management can be optimized in many ways, and Ace Infoway can assist OEMs with its comprehensive digital solutions services integrated with AI/ML capabilities.

Challenges Faced by OEMs For Not Data (AI/ML) Integrated Inventory Management

Our team has closely worked with stakeholders of different industry-specific OEMs- these are the common issues many OEMs faced before using Ace Infoways data (AI/ML) services to streamline their inventory management.

1) Inaccurate Demand Forecasting

Traditional systems often result in delays, with 43% of businesses reporting that manual processes lead to inaccurate inventory data.

- Stockouts and Overstocking: Lack of precise demand forecasting can lead to frequent stockouts or overstocking, causing lost sales or increased holding costs for OEMs.

- Inability to Identify Trends: OEMs might miss out on recognizing emerging market trends and seasonal patterns, leading to poor inventory planning.

2) Increased Human Errors

Manual inventory processes are error-prone, with up to 70-80% of inventory discrepancies attributed to human error. Manual processes like cycle counting and data entry are prone to human error leading to inaccurate inventory records, and inefficiencies in supply chain operations further hindering efficient production planning for OEMs.

3) Increased Lead-times

Limited data-sharing capabilities hinder collaboration. Integrated supply chain solutions can reduce lead times by up to 10-15% through improved coordination. Data (AI/ML) integration facilitates real-time data sharing, enhancing collaboration with suppliers and distributors.

4) Inefficient Production Planning

Without real-time data on inventory levels, production planning becomes a guessing game. This can lead to production delays if needed materials are unavailable or disruptions if finished goods pile up due to excess inventory.

5) Lack of Advanced Analytics

Traditional systems often lack advanced data analytics capabilities. Companies using data analytics tools report a remarkable reduction in overall inventory costs.

- Missed Patterns and Trends: Without AI/ML, OEMs may miss out on identifying hidden patterns and correlations in inventory data, leading to missed opportunities.

- Reactive Rather Than Proactive: OEMs may rely on reactive decision-making instead of proactive planning, resulting in suboptimal inventory management.

6) Poor Decision-Making

- Lack of Data-Driven Insights: The absence of AI-driven insights can hinder informed decision-making, leading to poor strategic planning.

- Ineffective Scenario Planning: OEMs may struggle with scenario planning and risk assessment, resulting in inadequate preparation for market fluctuations.

How Our Data (AI/ML) Services Can Streamline Inventory Management By 30-35% For OEMs?

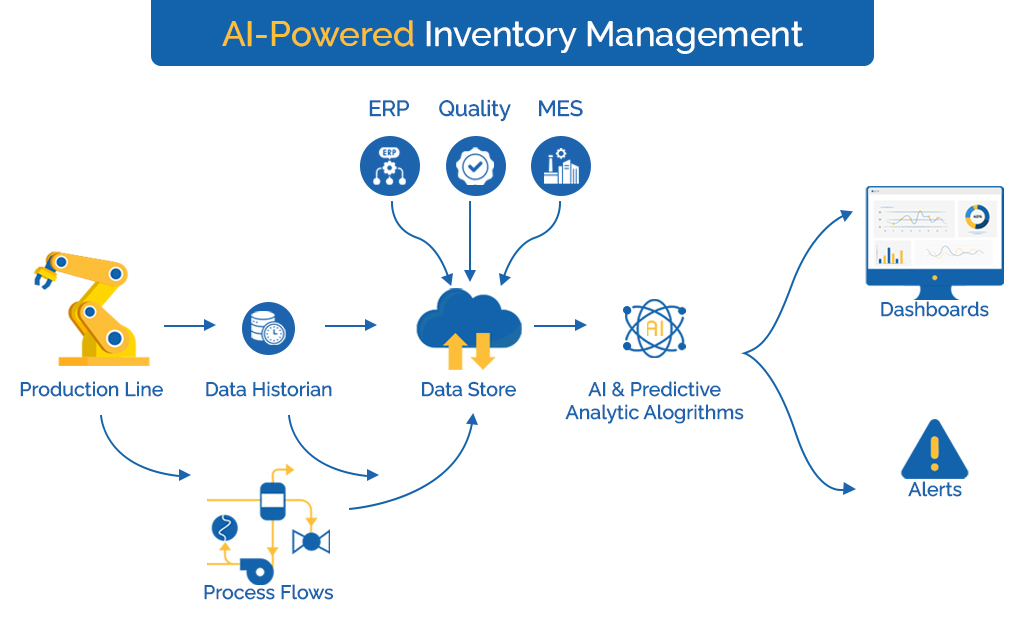

Our Data (AI/ML) integration services are not a single, monolithic approach but a spectrum of capabilities that enable machines and IT infrastructure of OEMs to mimic human intelligence, including learning from data, making predictions, and automating tasks.

With our Data (AI/ML) services, we have improved multiple aspects of inventory management, ranging from real-time data analysis to automated decision-making for OEMs all over the globe. This technology can process vast amounts of data quickly and accurately, without fatigue, making it an invaluable tool for optimizing and streamlining inventory management.

1) 40-50% Improvement In Inventory Tracking

- Data Collection and Analysis: Our data (AI/ML) services help rapidly gather and process data from sources like warehouse systems and e-commerce platforms, providing real-time inventory snapshots.

- Predictive Capabilities: AI predicts future demand based on historical data and market trends, enabling proactive inventory management for OEMs.

- Automation: We help develop models using data (AI/ML) and integrate it to enable automated inventory tracking and updates across multiple warehouses and sales channels, reducing errors, improving efficiency, and enabling quick responses to inventory issues.

Benefits of Accurate Inventory Tracking to OEMs

- Reduce overstock and understock situations.

- Improve production planning

- Optimize supply chain operations

2) 70-80% Accurate Inventory Forecasting

We leverage the capabilities of predictive analytics offering deep insights into inventory trends, turnover rates, historical sales data, and carrying costs. OEMs can leverage these insights to optimize their inventory management strategies and to make accurate predictions about future demand.

Additionally, AI/ML can incorporate various factors that influence demand, such as seasonal trends, market changes, and promotional activities. By considering all these variables, AI provides a more comprehensive and precise demand forecast.

Benefits of Accurate Inventory Forecasting

- Data-driven decision making

- Improve production planning

- Optimize supply chain operations

3) 35-40% Increase In Supply Chain Visibility

- Real-time Tracking: Our AI/ML integrated data solution services facilitate real-time tracking of goods throughout the supply chain, leveraging data from GPS, IoT devices, and RFID tags for accurate product movement monitoring.

- Predictive Analysis: Our AI/ML models analyze extensive supply chain data to forecast potential bottlenecks, demand fluctuations, and other challenges, enabling proactive measures for OEMs.

- Intelligent Reporting: The integrated AI/ML tools generate detailed reports on diverse supply chain activities, offering insights crucial for data-driven decision-making.

Benefits of Increase In Supply Chain Visibility to OEMs

- Reduced costs

- Increased sales

- Enhanced client service

4) 20-25% Improvement In Order Fulfillment Accuracy

- Automated Processing: The AI/ML-powered data solutions help in swiftly processing and prioritizing orders by considering factors like delivery location, inventory status, and customer preferences.

- Predictive Analytics: It helps OEMs forecast order volumes, allowing OEMs to anticipate demand and streamline fulfillment operations.

- Intelligent Recommendation: AI/ML integrated systems identify potential bottlenecks in order fulfillment and proactively address issues or provide recommendations for smoother operations.

Benefits of Having Improved Order Fulfillment Accuracy

- Enhanced customer experience

- Improved inventory turnover

- Accurate revenue realization

5) 25-35% Reduction In Poor Inventory Turnover

- Predictive Analytics: The AI/ML integrated models predict future demand using historical data, seasonality, market trends, and other factors, helping OEMs optimize stocking levels.

- Real-time Inventory Tracking: Leveraging data (AI/ML) capabilities we provide immediate insights into inventory levels, enabling swift responses to stock fluctuations.

- Supplier Interactions: We help integrating data (AI/ML) into the systems to optimize reordering processes, ensuring timely replenishment from suppliers to prevent stockouts for the OEMs.

Benefits Of Reduced Poor Inventory Turnover to OEMs

- Timely Deliveries

- Accurate Product Availability

- Increased Sales

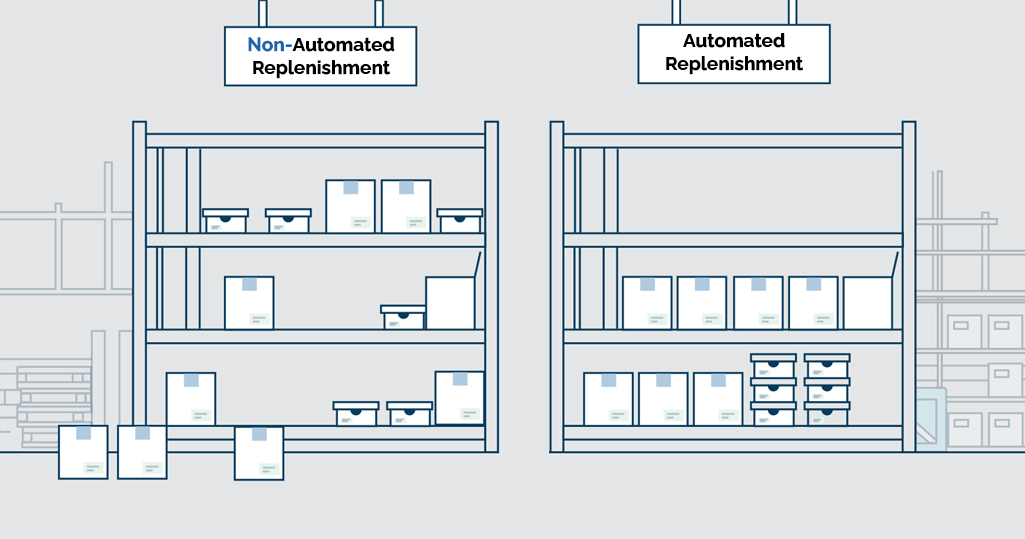

6) Automated Replenishment

- Automated Replenishment: Our data (AI/ML) integrated systems automatically reorder products upon reaching preset thresholds, minimizing human error and allowing staff to prioritize other tasks.

- Demand Forecasting: With predictive analytics, OEMs can precisely make demand forecasts, to help maintain optimal stock levels.

- Supplier Selection: AI aids in selecting the optimal supplier based on factors such as cost, delivery speed, and reliability for efficient restocking.

Benefits of Automated Replenishment to OEMs

- Enhanced efficiency in procurement processes

- Reducing supply chain disruptions

- Timely replenishment

Why Ace Infoway Is The First Choice For OEM Industries To Streamline Inventory Management?

- D2M: No, it’s not about Direct To Mobile, its about Direct To Management. To ensure the highest standards of quality and efficiency, our top executives, including the CEO, CXO, and CTO, are actively involved at every stage of the process. Our clients benefit from direct and unhindered access to these senior leaders throughout the project lifecycle. This hands-on approach ensures that every aspect of our service meets the stringent standards we set and guarantees timely delivery and top-notch service, from initial conception to final deployment.

- Client-centric Co-creation: Collaborating closely with clients throughout the project lifecycle to innovate and develop solutions that align perfectly with their goals and requirements.

- Agility and Flexibility: Ace Infoway emphasizes agility and scalability enabling rapid adaptation to evolving data landscapes and business requirements of OEMs. Unlike rigid solutions that struggle with agility, Ace Infoway’s approach ensures swift responsiveness to market changes and operational demands.

- Hyper-personalized Client Engagement: No one-size-fits-all; Tailoring our services to meet the unique needs and preferences of each client, ensuring a personalized experience that exceeds expectations.

Conclusion

Efficient inventory management can enhance OEM’s productivity, ROI, resource utilization, growth speed, and success rate. Thats why OEMs need a change, a shift from just using traditional inventory optimization software to a solution that addresses the big picture. Integrating data (AI/ML) into inventory management systems is an investment to make your OEM future-ready. It empowers data-driven decision-making, fosters agility, and ultimately, paves the way for increased profitability and customer satisfaction.

Contact us, to have a detailed consultation and discussion to address the challenges and queries about inventory management. Reach us, to know how we can help streamline your OEMs inventory management by 35% with our data (AI/ML) services.