Table of Contents

Manufacturers lose up to 40% of their operations to quality-related costs. Even thriving companies lose 10-15%, underscoring the urgent need for effective quality improvement programs.

The absence of robust analytics capabilities represents more than a missed opportunity—it signifies potential revenue left untapped. Manufacturers, especially in high-tech sectors, are discovering that without comprehensive visibility into their operations, they risk leaving significant financial gains on the table. This realization has propelled the adoption of advanced analytics tools, both at the edge and in the cloud, to unprecedented importance.

Particularly, by leveraging real-time data from customer-installed products, high-tech manufacturers can proactively offer tailored maintenance contracts, ensuring equipment operates at peak efficiency. This not only generates new revenue streams but also minimizes warranty-related expenses by preemptively addressing potential issues. Such strategic use of analytics not only optimizes operational performance but also enhances customer satisfaction—a critical factor in maintaining a competitive edge in today’s market.

Key Quality Control Hurdles That Manufacturers Face Today!

Maintaining high standards of quality control presents several challenges for manufacturers that require careful management and innovative solutions:

- Inconsistent Product Quality – Real-time monitoring to detect and address variability in production.

- Supply Chain Disruptions – Enhanced visibility and predictive analytics to manage and mitigate disruptions.

- Machinery Downtime – Predictive maintenance to prevent unexpected equipment failures.

- Manual Data Entry Errors – Automated data collection and analysis to eliminate human error.

- Delayed Defect Detection – Early detection of defects through continuous monitoring and advanced analytics.

- Limited Process Optimization – Insightful data analytics to identify inefficiencies and optimize production processes.

- Regulatory Compliance Issues – Automated tracking and documentation to ensure compliance with industry standards.

- Inadequate Root Cause Analysis – Detailed analytics to trace and resolve the root causes of quality issues.

- Variable Supplier Quality – Consistent monitoring of supplier performance and quality metrics.

- High Scrap and Rework Rates – Real-time quality control to reduce waste and rework.

- Inefficient Inventory Management – Improved forecasting and inventory control through data-driven insights.

- Poor Production Planning – Enhanced planning and scheduling with predictive analytics.

- Lack of Real-Time Visibility – Comprehensive, real-time insights into all aspects of the manufacturing process.

- Suboptimal Resource Utilization – Data-driven resource allocation to maximize efficiency.

- Difficulty in Scaling Operations – Scalable cloud solutions to support growth and adaptation to market changes.

By leveraging predictive analytics, manufacturers can forecast potential quality issues, optimize production processes, and ensure compliance with regulatory standards. Furthermore, cloud-based platforms streamline data integration across departments, providing a holistic view of quality metrics and enabling data-driven decision-making.

Now as we move into 2024, the manufacturing industry is gearing up for significant technological advancements. According to Gartner, a staggering 54% of manufacturers are planning to increase their technology spending this year. This surge in investment displays the critical role that cutting-edge technologies like AI, IoT, and Business Intelligence play in driving efficiency, innovation, and competitiveness.

Here’s How to Implement Cloud-Based Analytics for Better Quality Control

Implementing cloud-based analytics for better quality control is simpler than you might think. By following a few key steps, you can transform your quality control processes and unlock significant improvements in product quality and operational efficiency. Understand these essential steps:

-

Assessing Current Quality Control Processes and Challenges

The first step in implementing cloud-based analytics for quality control is a thorough assessment of your existing quality control processes. This involves identifying the key areas where quality issues arise, understanding the current methods and tools used for quality control, and pinpointing the specific challenges that hinder optimal performance.

Conducting a comprehensive audit helps in recognizing patterns of inefficiency, bottlenecks, and areas where data collection is either lacking or inconsistent. This foundational step sets the stage for targeted improvements and ensures that the transition to cloud-based analytics addresses the most critical issues.

-

Choosing the Right Cloud-Based Analytics Solution Provider

Selecting the right cloud-based analytics solution provider is crucial for the success of the implementation. Look for providers with a proven track record in the manufacturing sector and those who offer robust, scalable solutions tailored to your specific needs.

Key factors to consider include the provider’s expertise in handling large datasets, their ability to integrate seamlessly with existing systems, and the level of customer support they offer. Evaluate different providers based on their analytics capabilities, security features, and user-friendly interfaces.

Conducting trials or pilot programs can provide valuable insights into how well a solution aligns with your operational requirements.

-

Integration with Existing Systems (ERP, PLM, etc.)

Integrating cloud-based analytics with your existing systems is a critical step that requires careful planning and execution. This includes ensuring compatibility with Enterprise Resource Planning (ERP), Product Lifecycle Management (PLM), and other critical systems.

Seamless integration facilitates the flow of data across different platforms, providing a holistic view of your manufacturing operations. It’s essential to work closely with IT teams and solution providers to map out integration strategies, set up data pipelines, and establish protocols for real-time data synchronization.

Effective integration not only enhances data accuracy but also maximizes the utility of analytics insights across the organization.

-

Training and Adoption Strategies for Employees

The successful adoption of cloud-based analytics hinges on comprehensive training and buy-in from employees. Developing a structured training program that covers the functionalities and benefits of the new analytics tools is vital.

Tailor the training sessions to different user groups, from shop floor operators to management, ensuring everyone understands how to leverage the analytics to enhance quality control.

Additionally, fostering a culture of data-driven decision-making can accelerate the adoption process. Encourage open communication, address any concerns promptly, and highlight early successes to build confidence and enthusiasm.

Providing ongoing support and resources can help maintain momentum and ensure sustained usage of the analytics platform.

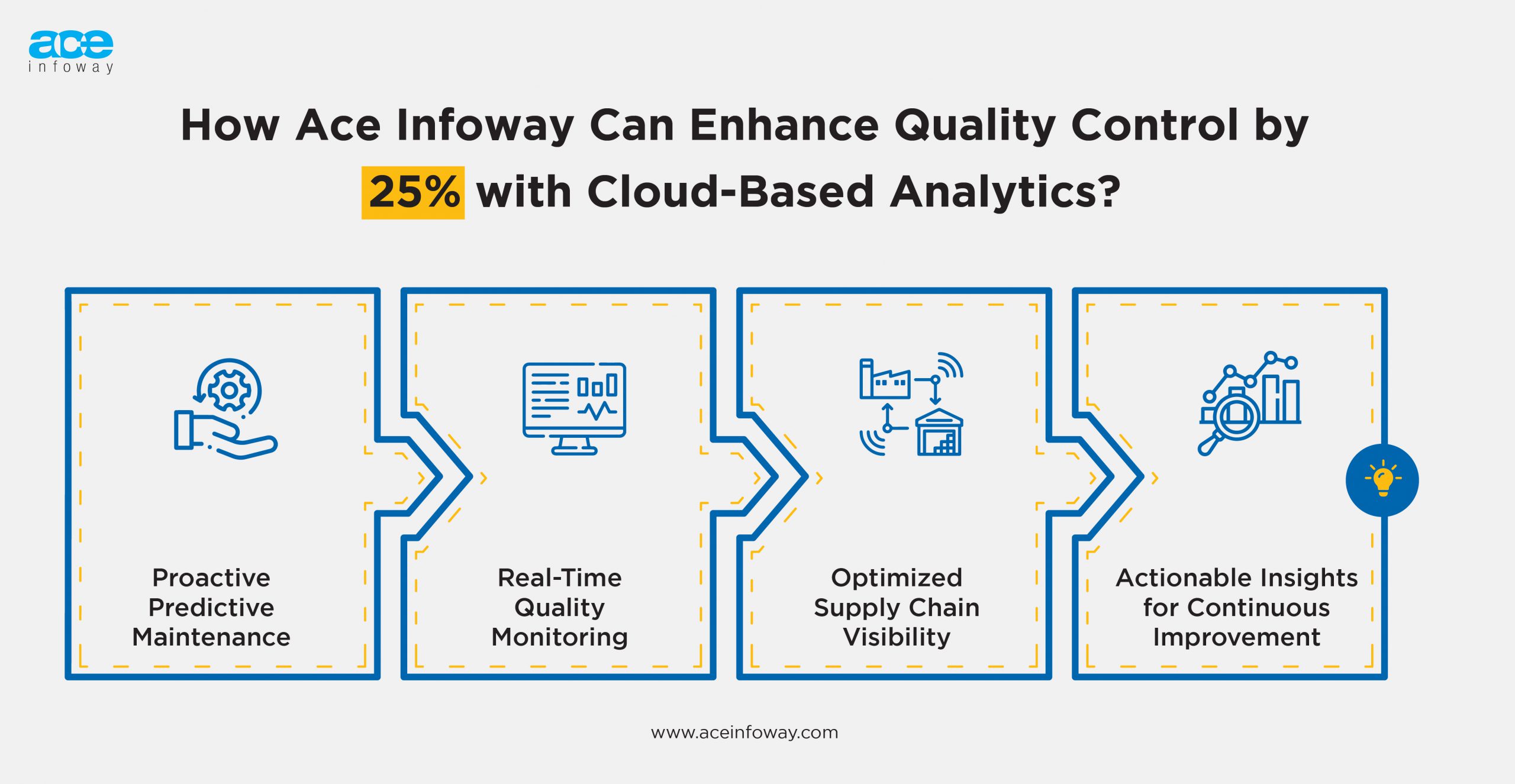

How Ace Infoway Can Enhance Quality Control by 25% with Cloud-Based Analytics?

At Ace Infoway, our journey with cloud-based analytics has reshaped how we approach quality control in manufacturing, yielding substantial improvements across critical areas:

- Proactive Predictive Maintenance: By integrating AI-driven predictive maintenance models with IoT sensors, we’ve transformed how we manage equipment health. This proactive approach has slashed unplanned downtime by 20%, ensuring our production lines operate at peak efficiency with minimal disruptions.

- Real-Time Quality Monitoring: Our implementation of real-time quality monitoring systems has been pivotal in catching deviations instantaneously. Through sophisticated anomaly detection algorithms, we’ve reduced defects by 15%, allowing us to address issues promptly and maintain stringent quality standards.

- Optimized Supply Chain Visibility: Leveraging cloud analytics, we’ve achieved end-to-end visibility across our supply chain—from suppliers to logistics. This transparency has streamlined inventory management, cut lead times by 30%, and ensured consistent quality in raw materials, enhancing the overall reliability of our products.

- Actionable Insights for Continuous Improvement: Our tailored quality insights dashboards consolidate data from diverse manufacturing processes. These analytics empower our decision-makers with actionable insights, enabling data-driven strategies to optimize operations and drive a targeted 25% enhancement in quality control metrics.

Through these initiatives, Ace Infoway continues to pioneer advancements in manufacturing quality control, leveraging cloud-based analytics to not only meet but exceed industry standards. Our commitment to innovation and quality underscores our dedication to delivering exceptional results for our clients and stakeholders alike.

Why Choose Ace Infoway for Your Manufacturing Needs?

Choosing Ace Infoway means partnering with a team dedicated to your success. Here’s why manufacturers love working with us:

- We tailor solutions to fit your exact needs.

- From idea to execution, we innovate with you.

- Our team is always here to support and guide you.

- Transparent communication and reliable results.

- Specialized knowledge to optimize your operations.

Experience the difference of working with a technology partner that prioritizes your business objectives and empowers you to achieve your goals with confidence.

End Note

Cloud-based analytics have emerged as a game-changer, offering manufacturers unprecedented insights, efficiency gains, and competitive advantages. And as you navigate the complexities of modern manufacturing, choosing the right technology partner is crucial. Whether through predictive maintenance, real-time quality monitoring, or enhanced supply chain visibility, our solutions are designed to optimize processes and elevate product quality. Let’s collaborate to build a resilient, efficient, and innovative manufacturing ecosystem that sets new benchmarks in quality and performance.